1300 737 976

Call us

Live Chat

Call us

In the realm of precision temperature measurement, AST (Accurate Sensors Technologies) has emerged as a pioneering force, offering advanced infrared pyrometers that redefine the way industries monitor and control temperature. Pyrosales distributes AST products to many different industries.

Infrared thermometers, often referred to as pyrometers or radiation thermometers, belong to subset of devices known as “thermal radiation thermometers.” These non-contact thermometers measure the temperature of an object based on the thermal radiation it emits. AST infrared pyrometers excel in this domain, offering precise readings without physical contact.

Origins of Thermometer: A Historical Perspective

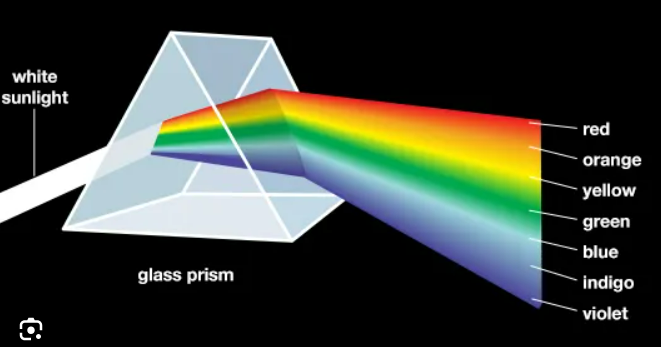

Herschel’s groundbreaking experiment involved using a prism to spread sunlight into the colour spectrum. By employing thermometers with blackened bulbs, he measured temperatures across different colours, discovering an increase temperature beyond the visible red range. This led to the term “calorific rays,” now known as “infrared” energy. Over time, advancements in technology have refined and shaped the contemporary infrared pyrometer, such as AST innovating offering.

How Infrared Thermometers Work.

Infrared Pyrometers utilise lenses to focus infrared light onto detector called a thermopile. This component absorbs the infrared radiation, converting it into heat. The amount of electricity generated correlates with the temperature of the objects being measured. This process enables AST infrared pyrometers to provide accurate and rapid temperature readings.

The applications of infrared thermometers are extensive and diverse. Industries such as steel, glass, and electrical frequently utilise these instruments for temperature monitoring. AST infrared pyrometers, including fixed, portable, and high-temperature variants, cater to the specific needs of various industrial processes.

Advantages of Using AST Infrared Pyrometers.

Pyrometers offer a host of advantages, making them indispensable in industrial applications:

What to consider when setting up a pyrometer system?

Setting up a pyrometer system in your industrial process there are a few crucial factors to consider, we have set up a few pointers on how to select what you require for your system.

Factor 1. You need to know what temperature range you need to measure, the distance between the pyrometer and the targeted object and any other specific requirements for your industrial measurement application.

Factor 2. Once you have determined your measurement requirements you need to select the correct pyrometer. There are many options with different configurations each one suited to different industrial applications. It is better to use a specialist like us Pyrosales to assist you in your selection with our expertise who can assist you in the correct selection.

Factor 3. The installation of the pyrometer system will require a specialist to ensure the pyrometer or pyrometers are mounted correctly and securely so there is no chance of vibration. Aligned with the targeted objects is crucial to have accurate temperature measurement.

Factor 4. The plant control system needs to be installed or connected to the pyrometer or pyrometers so monitoring can commence. You will need to configure your control system to receive the pyrometers signal and use it to control your temperature process.

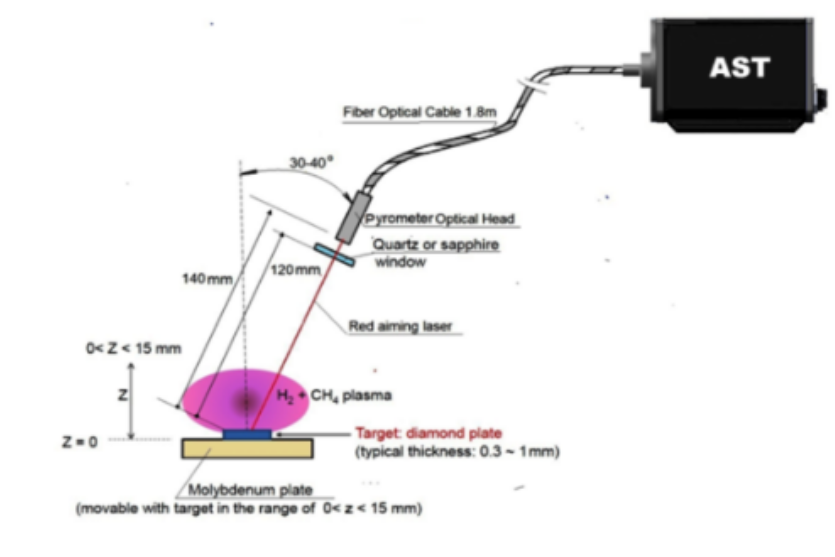

Pyrosales works very closely with our distributor of pyrometers Accurate Sensor Technologies (AST). An example of an AST system being used.

Example of Pyrometers for a Lab Grown Diamond.

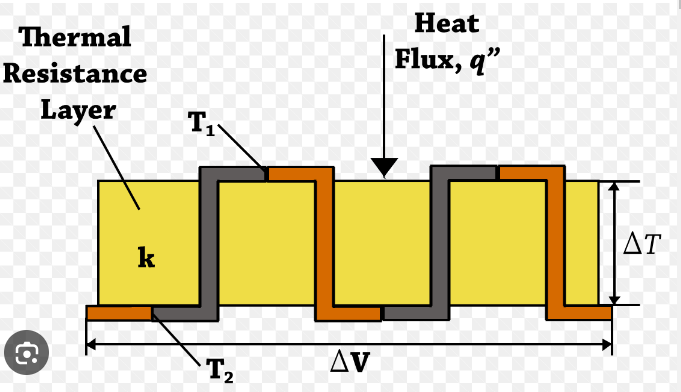

The method for producing diamonds includes positioning a diamond in a holder such that a thermal contact is made with a side surface of the diamond adjacent to an edge of a growth surface of the diamond, measuring temperature of the growth surface of the diamond to generate temperature measurements, controlling temperature of the growth surface based upon the temperature measurements and growing single crystal diamond by microwave plasma chemical vapour deposition on the growth surface, wherein the growth rate of the diamond is greater than 1μm per hour. In this entire process temperature plays a critical role. We need to measure the temperature of the target diamond rather than the plasma.

Temperature Measurement by Infrared Pyrometers.

Key Features

Pyrosales offer all AST models of Infrared Pyrometers. Pyrosales engineers are available to consult on various stages of any project, from the development and planning of a new project to modifying or upgrading an existing facility. Our staff is here to provide you with assistance and recommendations to ensure the best outcome and value. We are happy to visit our clients on-site or conduct meetings from one of our offices.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.