1300 737 976

Call us

Live Chat

Call us

The petrochemical sector is a vast arena encompassing a diverse range of products derived from petroleum and natural gas, included but not limited to plastics, detergents, cosmetics, solvents, fertiliser, synthetic fabrics, asphalt, and pharmaceuticals. The processes involved in the transforming raw materials into these end products involve intricate reactions, separation, and transformation, which all pivot around the core aspect of temperature control.

Central to the heart of these processes is the correlation between chemical reactions and catalysts, each uniquely reliant on specific temperature thresholds to yield optimal outcomes in terms of both quantity and quality. It’s within this context that thermocouple come into the fore, offering a combination of precision and adaptability across a wide spectrum of temperature. By providing real-time data on reaction temperatures, thermocouple empower operators to make informed adjustments, thereby not only boosting reaction efficiency but also mitigating potentially costly deviations that could jeopardise both the process and final product.

The petrochemical industry’s spectrum of processes is characterized not only by its intricate chemistry but also by exacting safety prerequisites. Many of the materials utilised within the processes can have corrosive properties or entail heightened flammability risks. In such hazardous and corrosive environments, the reliable functionality of temperature sensors becomes of paramount importance. Accurate temperature measurements not only safeguard the integrity of the ongoing process but also play a crucial role in ensuring the well-being of personnel and the longevity of equipment.

Temperature ranges within which thermocouples operate within the petrochemical sector are broad. The demands span from cryogenic temperatures, prevalent in gas production plummeting well below zero, to surpassing 800°C (1472°F) in operations such as cracking and sulphur recovery furnaces, as well as flare systems. The adaptability of thermocouples to this extensive range of thermal conditions shows thermocouples engineering prowess and utility.

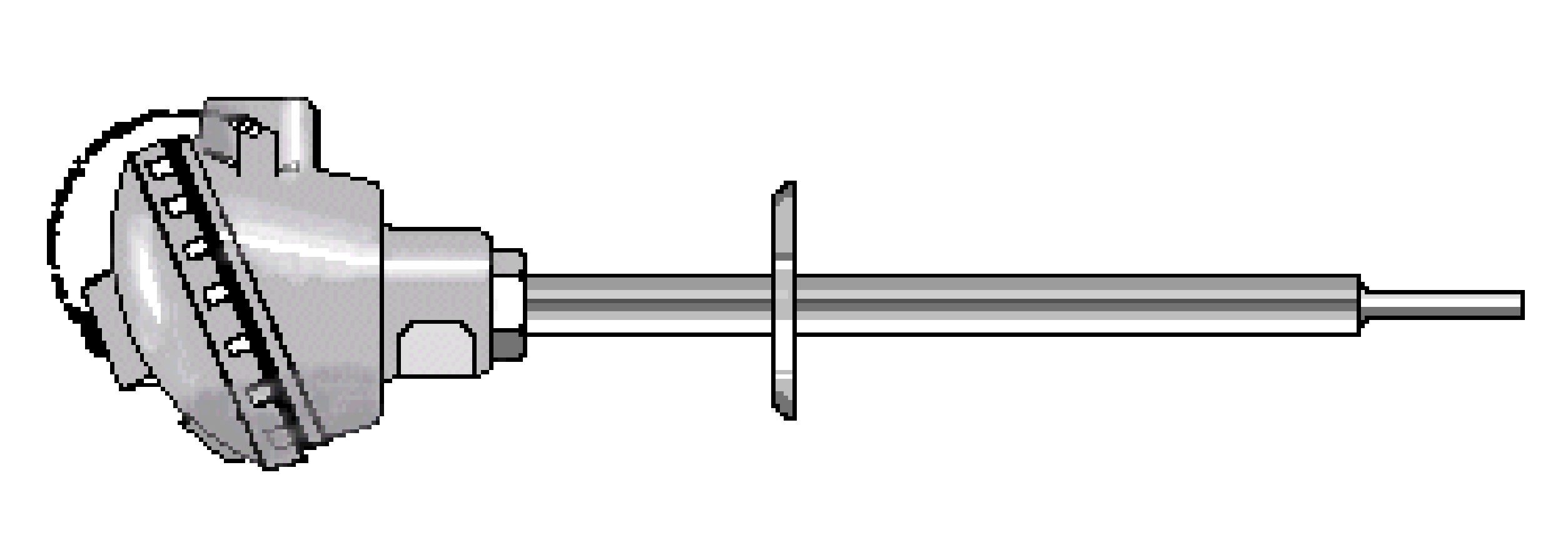

To address these diverse and often extreme temperature requirements, an array of materials and sensor solutions have been meticulously designed. Pyrosales, offers an extensive range of specialised thermocouple options to meet the unique demands of the petrochemical industry. From standard thermowell assemblies to special tube skin thermocouples and high-temperature ceramic sheathed variants, the range caters to the industry’s evolving needs. Pyrosales also offers specialised materials such as Hastelloy®, Incoloy®, Tantalum, as well as protective coatings such as PTFE, to ensure all design and chemical temperature requirements can be meet.

For the Petrochemical industry we use special components with the thermocouple, such as thermowells which are used on flue gas area of boilers, furnaces, kilns, heat recovery units, incinerators, reformers and gasifiers, material of construction is recommended based on the working temperature, pressure, and other process parameters. The general guideline for selection of materials for protecting tubes can be regarded as given in the table below.

The dimensions of the thermocouple, thermowell and protective sheath will depend on the process application parameters.

The use of ceramic protection tubes are commonly used for high temperature applications, they have a property of transmitting electric force without conduction and a high resistance to thermal shock. The protection sheath/ceramic are primarily used in thermocouple Types R, S, and B. The table below is a guide.

HEXOLOY Ò SA

It is well known that Silicon Carbide affords excellent resistance to erosive and chemical attack in reducing atmospheres. Its use as a heating element also confirms its suitability for use in high temperature applications. In its standard form, though, because it contains free silica, it is readily attacked in strong oxidising environments.

With the development of Hexoloy SA sintered silicon carbide, a silicon carbide material with no free silica now offers superior chemical resistance in both reducing and oxidising environments.

The properties of Hexoloy SA make it an ideal candidate for thermocouple protection sheaths:

Areas where Hexoloy SA has been successfully used include: – mineral processing, non-ferrous melting, and refining, high temperature process furnaces, chemical incinerators, recuperators, and corrosive chemical processing streams. Its high temperature capabilities have made it extremely effective in the coal processing industry, including gasification at temperatures above 1600oC.

METAL CERAMIC (LT-1)

It has high thermal conductivity and is superior to ceramics in thermal shock capabilities but should still be preheated before immersion into molten metals.

It is recommended for use in the following process environments:

As the chromium phase becomes reactive at elevated temperatures metal ceramics are not recommended for use in carburising or nitriding atmospheres, or in molten aluminium. It has a maximum continuous temperature rating of 1400oC.

While there may not be an ideal protection sheath for every process environment, Pyrosales will select, after analysing your required process conditions, the most suitable thermocouple/sheath/thermowell combination to best suit your needs. We will design the most cost-effective solution to your process.

Pyrosales engineers are available to consult on various stages of any project, from the development and planning of a new project to modifying or upgrading an existing facility. Our staff is here to provide you with assistance and recommendations to ensure the best outcome and value. We are happy to visit our clients on-site or conduct meetings from one of our offices…

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.