1300 737 976

Call us

Live Chat

Call us

Thermowells are recommended whenever a temperature element is to be inserted into a process where corrosion, pressure, abrasion, or shear forces may threaten the life of the element. In addition, thermowells allow for a defective instrument to be removed without shutting down or draining the process.

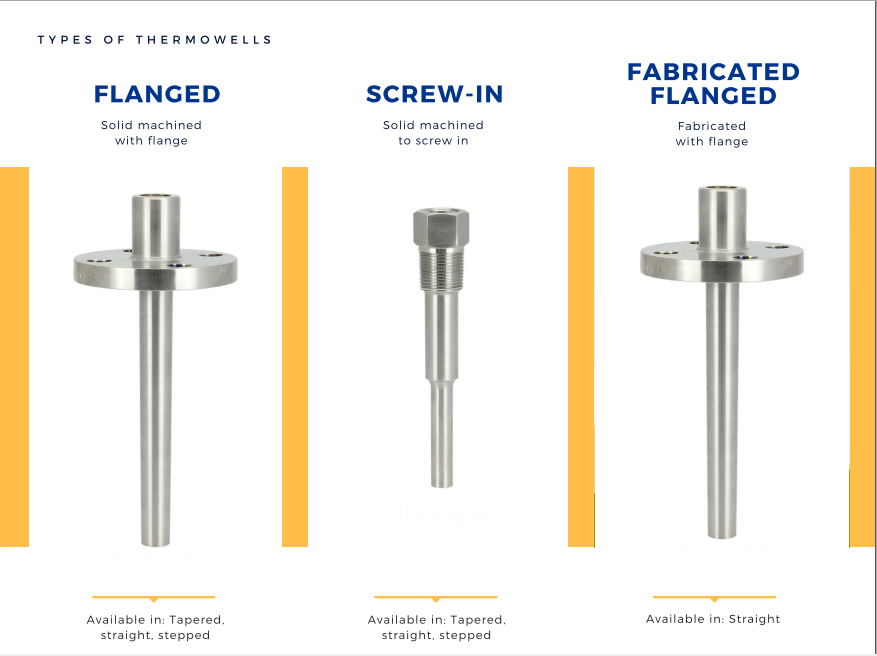

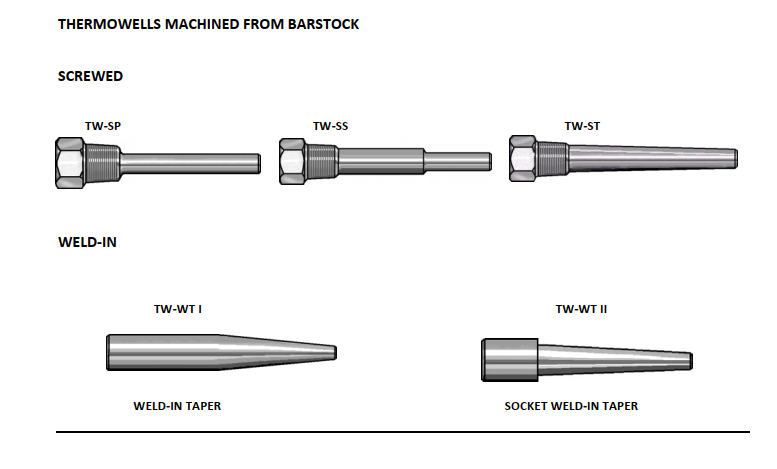

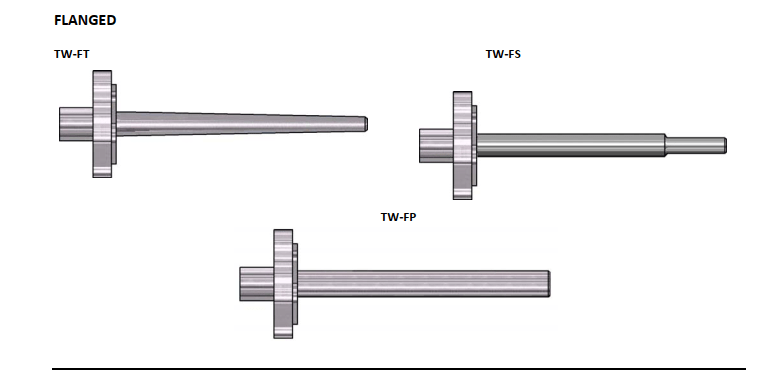

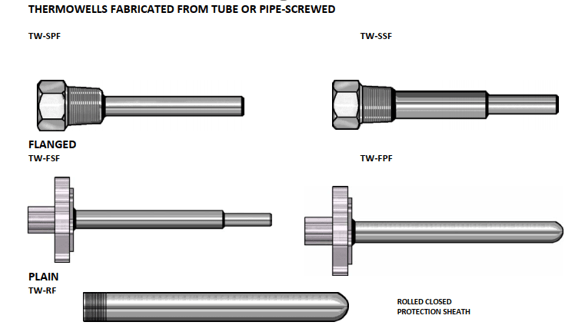

They fit into three broad categories: screwed, flanged, or weld-in, and can be designed to accept thermocouples, RTDs, temperature gauges or filled systems.

Thermowells Machined from Barstock.

Other services include post weld heat treatment, stress, and frequency calculations to ASME PTC 19.3. These all ensure that the thermowell design is suitable for the required process conditions.

THERMOWELL MATERIAL SPECIFICATIONS

Inconel® 625

A nickel‐chromium alloy with excellent resistance to pitting and crevice corrosion, unaffected by radiation embrittlement; widely used in aerospace applications and in marine environments. Good weld-ability can be used in the as‐welded condition. Maximum temperature: 1093°C.

Incoloy® 800

Superior to alloy 600 in sulphur, cyanide salts and neutral salts. Extensively used in steam/hydrocarbon reforming plants for pigtail piping, manifolds, and waste heat boilers, and in the internal components of secondary reformers. Widely used in heat treatment equipment and as a heater sheath material. Maximum temperature: 1093°C.

Incoloy® 825

A nickel‐iron‐chromium alloy with exceptional resistance to many corrosive environments. Superior to almost all metallic materials for handling sulphuric acid and shows excellent resistance to phosphoric acid. Widely used in chemical processing, oil and gas recovery, acid production, pickling operations, nuclear fuel reprocessing, and handling of radioactive wastes. Maximum temperature: 540°C.

Incoloy® MA956

An iron‐chromium‐aluminium alloy produced by mechanical alloying, it features great strength at high temperatures with excellent resistance to oxidation, carburisation, and hot corrosion. These properties make it especially suitable for gas‐turbine combustion chambers and other aggressive environments containing sulphur and chloride salts. Maximum temperature: 1350°C.

Monel® 400

Nickel‐copper alloy with very good corrosion resistance, commonly used to handle sea water, hydrofluoric acid, sulphuric acid, hydrochloric acid, and most alkalis. Typical applications include marine fixtures, chemical processing equipment, gasoline and water tanks, process vessels and piping and boiler feedwater heaters. Maximum temperature: 538°C.

Hastelloy® C276

Nickel‐molybdenum‐chromium alloy with excellent corrosion resistance especially in chlorinated environments. Widely used in chemical plants where it tolerates ferric and cupric chlorides, solvents, chlorine, formic acid, acetic acid, brine, wet chlorine gas and hypochlorite. Can be easily welded and maintains its properties in the as‐welded condition. Maximum temperature: 1093°C.

Hastelloy® B3

A development of the well‐established B2 alloy with improved thermal stability, fabricability and stress corrosion cracking resistance. It is the alloy of choice for handling hydrochloric acid in all concentrations and temperatures; it also withstands hydrogen chloride, sulphuric, acetic, hydrofluoric, and phosphoric acids. Maximum temperature: 538°C, up to 816°C in reducing or vacuum environment.

Hastelloy® C22

A nickel‐chromium‐molybdenum‐tungsten alloy with outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It shows exceptional resistance to a wide range of chemical process environments, such as ferric and cupric chlorides, chlorine, hot contaminated solutions, formic and acetic acids and seawater or brine solutions. The material has superior weld-ability and retains its properties in the as‐welded state.

Hastelloy® X

A high temperature alloy with excellent resistance to oxidising, reducing and neutral atmospheric conditions. Is widely used in aircraft jet engine components. Very good high temperature strength makes it ideal for furnace applications. Resistant to stress corrosion cracking in petrochemical applications. Maximum Temperature: 1204°C.

Haynes alloy 214

Excellent high temperature material, with the highest resistance to oxidation and carburisation of almost any alloy, it is recommended for temperatures of 950°C and above, it shows useful resistance up to 1315°C but its strength is severely reduced. Applications include ceramic firing furnace parts, automotive catalytic converter internals and in the industrial heating industry furnace flame hoods and rotary calciners. Has good resistance to chlorine contaminated environments, which allows its use in hospital waste incinerators. Maximum temperature: 1204°C.

Haynes alloy 230

Excellent high temperature strength, oxidation resistance and long term thermal stability. Used in aerospace, chemical processing and high temperature heating applications. Recommended for use in nitriding environments. Maximum temperature: 1149°C.

Haynes alloy 556

A multipurpose alloy which offers good resistance to sulphidising, carburising and chlorine bearing atmospheres. Common applications include waste incinerators, petroleum processes where sulphur is present, chloride salt baths, exhaust gas probes, the alloy is one of very few that can survive in molten zinc, making it ideal for galvanising processes. Maximum temperature: 1093°C.

Haynes alloy HR160

A high temperature alloy with outstanding resistance to high temperature corrosion, it has excellent resistance to sulphidation, and chloride attack in both reducing and oxidising atmospheres. Its resistance to attack by the products of combustion of low‐grade fuels makes it particularly useful in municipal, industrial, hazardous, and nuclear waste incinerators. Maximum temperature: 1204°C.

Titanium

A lightweight material with good strength in the 150 ‐ 470°C range. Excellent resistance to oxidising acids such as nitric or chromic. Also resistant to inorganic chloride solutions, chlorinated organic compounds and moist chlorine gas. Its good resistance to seawater and salt spray allows it to be used in offshore installations. Can be welded with special precautions to protect from atmospheric contamination.

Tantalum

Refractory metal that is ductile. Use only in inert atmospheres or very good vacuums. <10(‐3) torr. Hydrogen and nitrogen will react with tantalum above 400°C (750°F) resulting in nitride and hydride formation that will affect life. Tantalum is almost completely immune to chemical attack at temperatures below 150°C, and is attacked only by hydrofluoric acid, acidic solutions containing the fluoride ion, and free sulphur trioxide. Alkalis attack it slowly. At high temperatures, tantalum becomes much more reactive. Normally used by cladding a thin layer onto a less expensive material, such as steel or stainless-steel Tantalum’s corrosion resistance is like that of glass, making it the material of choice in critical chemical and pharmaceutical processes requiring maximum corrosion resistance and minimum contamination. Typical applications are: Chemical production (HCl, H2SO4), insecticides, pharmaceuticals, fine chemicals, explosives, plastics, dyestuff’s, condensation of phosgene derivatives, synthetic fibers, chromic acid plating solutions and operations involving chlorine, bromine, iodine and their compounds, high purity product manufacturing (cosmetics, soaps, perfumes) and separation of high boiling organic acids.

FOR MORE INFORMATION CONTACT US

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.