1300 737 976

Call us

Live Chat

Call us

In the realm of temperature measurement, few devices hold as much significance as thermocouples. These seemingly simple instruments are pivotal in various industries, from manufacturing and petrochemical to aerospace and healthcare. In this article we delve into the intricate mechanisms, applications, and challenges surrounding thermocouples, shedding light on the fundamental principles and practical implications.

At the heart of every thermocouple lies a simple yet profound principle: The Seebeck Effect. This phenomenon, discovered by Thomas Seebeck in 1821, elucidates the relationship between temperature differentials and electrical voltage in dissimilar conductors. When two different metals are joined at one end and subjected to a temperature gradient, they generate a small electrical potential proportional to the temperature difference a phenomenon known as The Seebeck effect.

Contrary to popular belief, the generation of Electric and Magnetic Fields (EMF) in thermocouples is not confined to the hot junction alone. Instead, EMF permeates throughout the length of both metal legs, driven by the disparities in the Seebeck coefficients of the respective metals. Factors such as contamination, oxidation, strain, and heat treatment can alter the Seebeck coefficients, thereby influencing the thermocouple output.

What is a Thermocouple Junction?

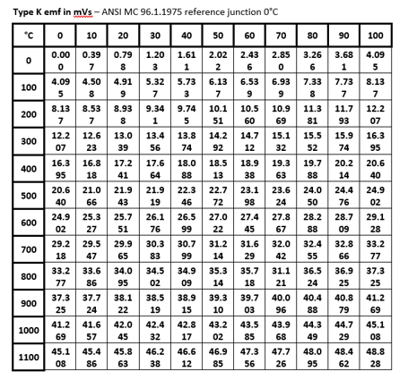

Thermocouples have two junctions, a hot junction, where the dissimilar metals are joined, and a cold junction. The cold junction is referenced to 0oC. Thermocouple outputs vary determine EMF values at different temperatures for different types of thermocouples. A problem that occurs is that the cold junction is usually at a temperature other than 0oC. Let us assume that we wish to determine the temperature of a process using a voltmeter to measure the mV output and a glass thermometer to measure the cold junction temperature. If we have a signal output of 9.340 mV and cold junction temperature of 27oC, the value of 9.340 mV should not be fed directly into the reference tables, because it is inappropriate. If we did, it would read 300oC, and if the cold junction temperature were added, as is a common notion, then a temperature of 327oC would be obtained. Let us now compare this with the correct result. The measured value is 9.340mV, which is the temperature gradient from 300oC to 27oC. What is missing is the gradient from 27oC to 0oC, which is 0.712 mV. Therefore, the correct mV output is 9.340 + 0.712 which equals 10.052 mV. When we look up the table, we read a temperature of 320oC – a difference of 7oC.

Manufacture of MIMS Thermocouples.

Care must be taken during the manufacture of thermocouples to ensure that contaminants are not present, and in the case of MIMS, that moisture is not present prior to sealing the thermocouple. To ensure that contaminants are not created during welding, TIG welding techniques are used. By using an argon shield you achieve an oxygen-free weld that ensures that scaling and oxidisation do not occur. It is also good practice to weld close the thermocouple with the same material as the sheath if MIMS thermocouples are being manufactured. Moisture is eliminated by either placing the thermocouple in a drying oven or heating the thermocouple with an oxy-torch to ensure that any moisture in the magnesium oxide insulation has been driven out. These techniques are used for the hot junction. The cold junction must also be protected against contaminants i.e. it should be housed in a suitable enclosure that will inhibit the ingress of foreign gases, particles, and moisture.

There are basically three types of hot junction:

• Exposed.

• Grounded.

• Ungrounded.

The choice of the hot junction will be dependent upon the response of the thermocouple, contamination hazards, physical restraints, and electrical earthing considerations.

Base Metal Thermocouples

The base metal thermocouples are made from basic metallic element alloys (iron, copper & nickel). Base metal thermocouples with the ANSI standard are E, J, K, N & T, and are usually used for temperatures up to1200oC.

Rare Metal Thermocouples

These are often designated as “Noble Metal “thermocouples and are generally designated to

thermocouples with conductors made from platinum and/or platinum alloys. They consist mainly of the type B, R & S, and are typically used for high-temperature applications above 1200oC.

Mineral Insulated Thermocouples

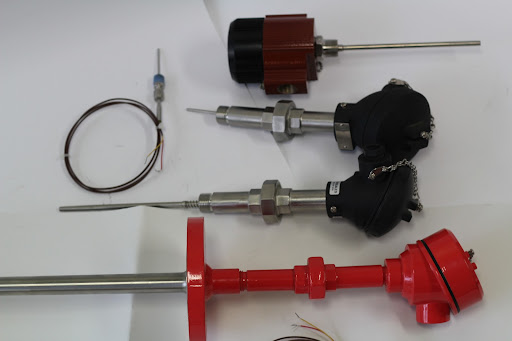

Developments in sheathing materials & integral sheath/elements combinations allow the use of K & N thermocouples for higher temperatures. The mineral insulated thermocouples can be classified as a modern development. The mineral insulated metal sheathed (MIMS) thermocouple was introduced about 50 years ago, and it has revolutionised the temperature measuring industry. It has provided a compact design where the element is packaged in a protective environment.

THERMOCOUPLE FUNDAMENTALS

Service Life.

Useful thermocouple life is a very difficult prediction to make, even when most of the details of an application are known. And unfortunately, such information is often very hard to determine. The very best test for any application is to install the unit, use, and evaluate the in-use performance of a design that is thought likely to succeed. The recommendations, and non-recommendations, listed under the thermocouple type descriptions are a good place to start when first selecting an assembly style to install in a process.

DECALIBRATION AND DRIFT

Stability.

Because the thermoelectric emf resulting from a given temperature difference is sensitive to changes in the chemical and metallurgical properties of the wire, the total emf produced by a used probe can be different from an otherwise identical new one under the same conditions. The changes are usually small (often negligibly small) over appreciable periods of time. But under adverse conditions, it is possible to realize large drifts at rapid rates.

To achieve long and reliable thermocouple life, the usual strategy is to operate the device comfortably under its maximum temperature and provide it with the cleanest possible environment in which to work. Enclosures, such as sheaths, protecting tubes, and thermowells, are the usual means of controlling the conditions that surround the thermoelements themselves.

What can go wrong?

Human error can be a contributing factor as well. Controls may be improperly set, connections may be improperly made, and inappropriate action in response to the operating conditions may be taken by mistake. Redundancy in instrumentation combined with training and responsibility are the usual means to combat these kinds of errors.

TROUBLESHOOTING

The approach.

To assess the problem, check if the system performance seems to be reasonable for the conditions: Do changes in the controls produce a logical result? What about the product? Does its condition correspond with what the instruments are saying?

How to test a used thermocouple.

The best way to evaluate a used thermocouple is to ‘probe’ the location by placing a new thermocouple that has a known output, alongside the suspect one in an operating process, and compare the readings. If it is not practical to have two sensors in place at the same time. Remove the suspect probe and replace it with another one known to be good. Then, if the good probe is in the same place as the removed one has been, and the process has not changed during the exchange, the readings from the two probes can be compared.

Note that it is not necessary to keep and use an unlimited supply of new probes for these tests. A few suitable replacement devices can be kept available, selecting one for testing use. Under normal circumstances, thermocouple drift, or degradation, is a gradual and very slow process. A single replacement probe can therefore be used several times to probe a process and be considered reliable for several repeated tests. And, when a drifted probe has been found, the test probe may simply be left in place as a working sensor, while the next replacement becomes the test device.

A useful instrument for troubleshooting thermocouple systems is a portable temperature indicator. A number of these devices can operate with two or more different thermocouple types, and some offer an ‘output’ function that will produce an electrical output to simulate a thermocouple operating at any temperature of choice.

In use, the instrument is normally attached to the wires of a circuit being tested at some convenient access point, such as in a connecting head. Care should be taken to ensure that the correct polarity is maintained. In Australia, we use the ANSI colour code where the negative is always RED. There, the output of an operating sensor may be monitored and evaluated. Or, using an instrument’s ‘output’ function, a simulated thermocouple signal may be sent back to the circuit’s permanent indicator or controller to verify the proper operation of the rest of the circuit. When driving a signal back towards an instrument, it is usually necessary to break one side of the circuit to avoid ‘loading’ the portable tester by the low resistance of the thermocouple itself.

Sections of extension wiring in thermocouple circuits can also be checked for proper connections with a portable tester. The section being tested should be electrically isolated from the rest of the loop, and one end of an extension wire pair should be shorted together. If a tester is connected to the opposite end of the shorted pair, the tester should indicate the approximate temperature of the shorted end. Note that if both ends of the extension pair happen to be at the same temperature, it may be necessary to warm the shorted end a little and verify that the tester ‘sees’ the temperature change correctly. The possibility of an incorrect, reversed connection is being checked in this test.

Pyrosales engineers are available to consult on various stages of any project, from the development and planning of a new project to modifying or upgrading an existing facility. Our staff is here to provide you with assistance and recommendations to ensure the best outcome and value. We are happy to visit our clients on-site or conduct meetings from one of our offices.

Pyrosales Pty Ltd has been assessed and approved by QAS International Ltd to ensure we adhere to quality management systems, standards, and guidelines. We continue to hold this certification by maintaining our work and quality practices.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.