1300 737 976

Call us

Live Chat

Call us

Temperature is one of the most important units of measurement that industries monitor. It is extremely imperative that temperature be as accurate as possible. If it is not managed correctly it can result in poorer quality items. A great smelling perfume, now smells ordinary, food may have a different flavour or in the medical field mismanagement of temperature can result in being unable to use donated items, such as blood.

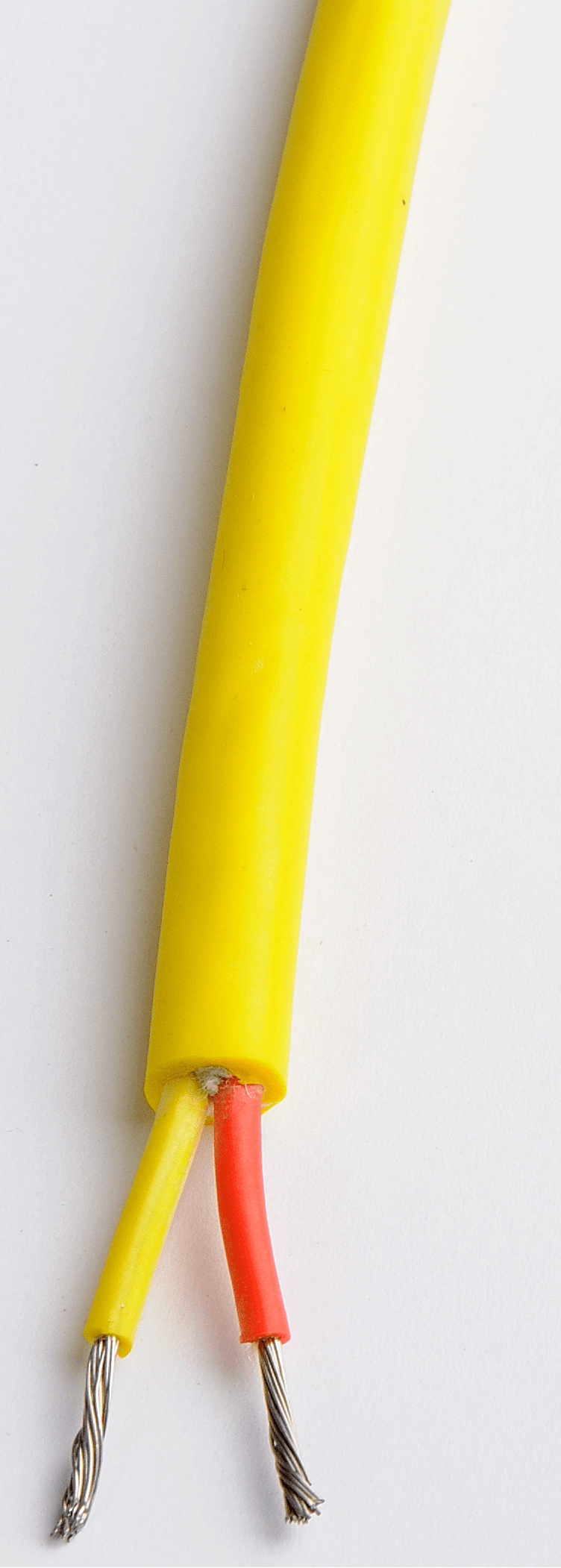

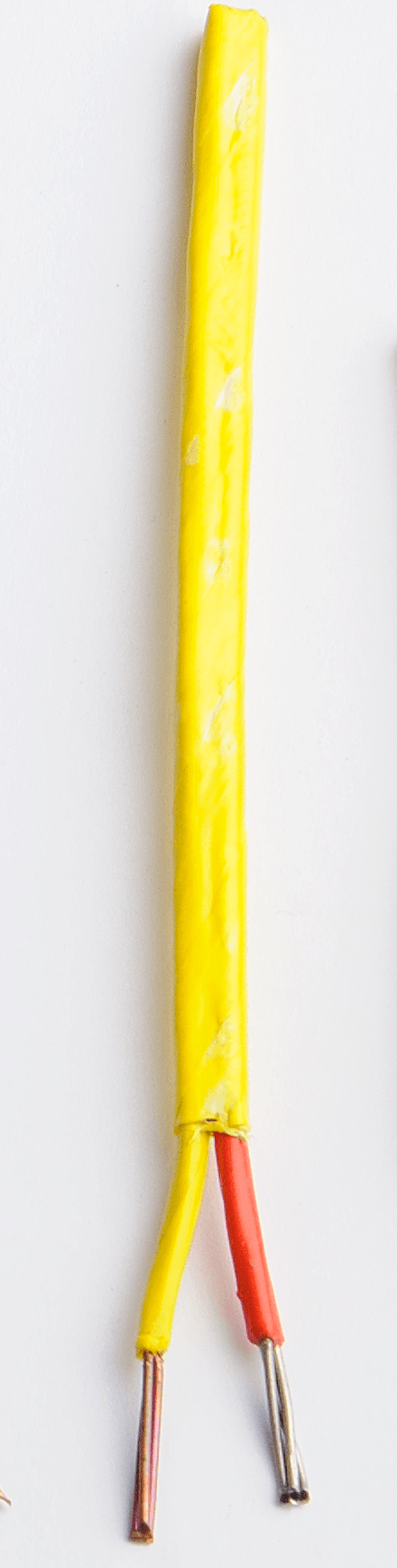

A thermocouple is a commonly used sensor for measuring temperature. The wire and cable for thermocouples and temperature sensors are a vital part of the construction, as they complete the circuit between the thermocouple and the RTD controller. Essentially, this is what carries the signal from the thermocouple to the RTD which converts the temperature into an accurate reading. The outer insulation around the thermocouple wires as well as some single conductors are colour coded for easy identification.

Pyrosales provide a wide range of temperature sensor wire and cables using various high performance materials. They have been manufactured at the highest quality.

Below is a description of the different materials used in thermocouple wire and cables, as well as the applications which they can be used in.

There are a variety of applications which would be appropriate to use these cables, including:

Suitable applications for fibreglass wire and cable to be used, include, but not limited to:

The applications which are well suited to PVC wire and cable include:

FEP/PFA/PTFE- each single conductor as well as the outer jacket is layered with FEP/PFA/PTFE. These wires are known to have exceptional moisture, chemical and abrasion resistance.

Applications which are suitable to use FEP/PFA/PTFE wires include:

Tape wire and cable are fitting to many applications which include:

To speak to a sales consultant, contact us today.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.