1300 737 976

Call us

Live Chat

Call us

Leakages in industrial production process has always been a safety concerns, time consuming and labour-intensive inspection problems because it is invisible to the naked eye. The InfiRay G600 Uncooled Infrared Camera can assist in the detection of leaks natural gas (CH4), refrigerant (freon), ammonia (NH3), sulphur hexafluoride (SF6) and other gases The non-contact method of thermal imaging helps quickly to locate the location of gas leakage.

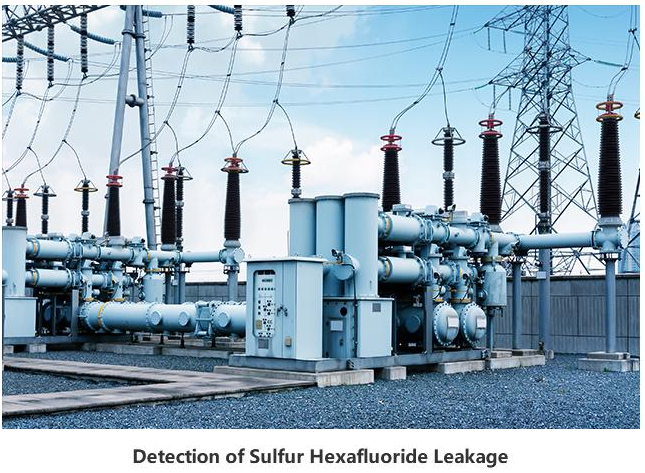

Sulphur Hexafluoride (SF6) is renowned for its extensive use in various industries, particularly in electrical equipment and a tracer gas. However, its release into the atmosphere contributes significantly to global warming, and its long atmospheric lifetime magnifies its impact. Detecting and mitigating SF6 leakages is pivotal in curbing the escalation of climate change and ensuring a sustainable future.

Ammonia (NH3), is a vital component in various industrial, include refrigeration, agriculture, and chemical production. Ammonia poses significant health risks when leaked into the environment. Detecting and preventing ammonia leakage is crucial to ensuring workplace safety, protecting ecosystems, and preventing harm to human health.

Refrigeration systems, whether found in household appliance, commercial freezers, or industrial setups, rely on refrigerants (freon), to transfer heat and maintain desired temperatures. Leaks in these systems can lead to issues. Efficiency Reduction: refrigerants leak result in loss of charge, forcing system to work harder for cooling. This drives up energy consumption, accelerates component wear, and shortens equipment lifespan. Environmental Impacts: many refrigerants are potent greenhouse gases, contributing to global warming when released. Health and Safety Concern: some refrigerants pose health risks upon exposure. Detecting leaks promptly helps protect individuals working or living near these systems from potential respiratory issues and skin irritations.

Natural gas is a valuable energy source used for heating, cooking, and powered various industrial processes. However, its invisible and odorless nature can make detecting leaks and ensuring safety a challenging task. Routine inspections are essential to identify potential gas leaks and mitigate the risks associated with them. Natural gas is not only flammable but can also displace oxygen, posing serious safety threats to both life, property from emissions explosions and fires.

Introducing the InfiRay G600 Thermal Imaging Camera.

The InfiRay G600 Uncooled Infrared Camera for Gas detection is equipped with advanced features that revolutionise the process of gas leak detection.

Extensive Gas Species Detection: The camera can observe dozens of gases, carefully selected infrared bands enable the identification of various gases, facilitating targeted leak detection.

Exceptional Sensitivity: With an approximate thermal sensitivity of 23mK, the G600 can capture even minute amounts of gas, enhancing its ability to detect leaks accurately.

Precise Spatial Resolution: The camera’s 23° custom lens provides a spatial resolution as low as 0.63mrad, allowing for finer das leak details or a wider working distance.

Gas leak detection is a critical aspect of safety, environmental protection, and operational efficiency across various industries. The InfiRay G600 Uncooled Infrared Camera revolutionises this process by providing real-time visualisation, extensive coverage, high accuracy, and integration with existing workflows. By incorporating the advance capabilities of the G600, industries contribute to sustainable practises, safer environments, and more responsible energy management, ultimately creating a positive impact on bold human well-being and the planet.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.