1300 737 976

Call us

Live Chat

Call us

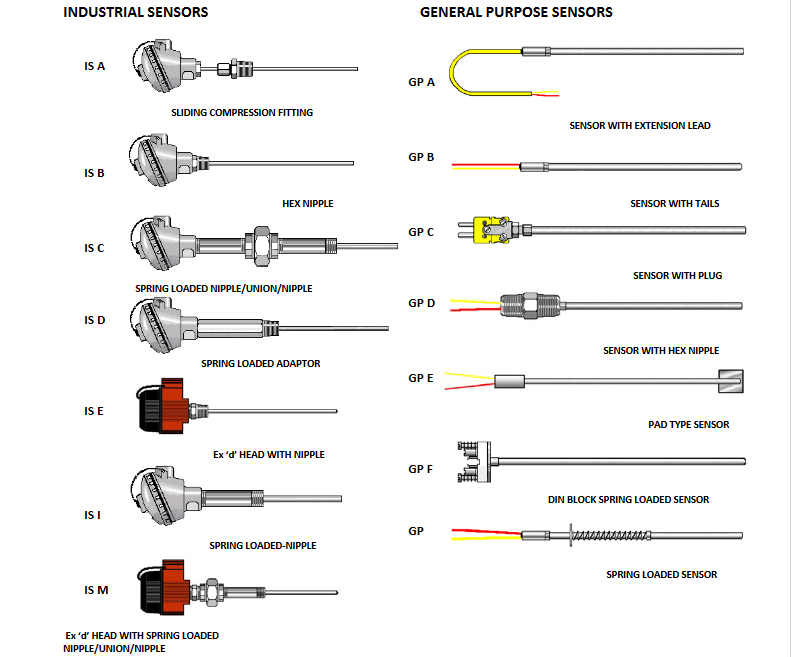

Pyrosales have been producing temperature solutions for numerous industries for more than 47 years. Our products are constantly being updated to meet the challenging and ever-changing production techniques of most manufacturing processes. We specialise in custom designed and engineered solutions. Below is an overview of the variety of sensors Pyrosales manufacture and the accessories available.

MINERAL INSULATED THERMOCOUPLE ASSEMBLIES: The metal‐sheathed, mineral‐insulated thermocouple has become the accepted norm in most industries. It features a variety of temperature and corrosion resistant sheaths, and extremely high purity (96% or better). Magnesium oxide (MgO) insulation.

BASE‐METAL THERMOCOUPLE ASSEMBLIES:

The base‐metal thermocouple covers the majority of applications within the industry over a range of ‐80°C to +1300°C.

Type T Copper Constantan ‐180°C to +400°C

Type J Iron Constantan 0°C to +750°C

Type E Chromel® Constantan 0°C to +900°C

Type K Chromel® Alumel® 0°C to +1200°C

Type N Nicrosil Nisil 0°C to +1300 °C

The base‐metal element is available in two basic forms: (1) Bare Wire and Beads, and (2) Mineral insulated. (Details are on a separate sheet called Mineral insulated thermocouples). The bare wire and bead construction normally requires additional protection from the medium being measured. The mineral insulated system, however, can be used on its own, except in particularly severe conditions, such as in aluminium or brass foundries.

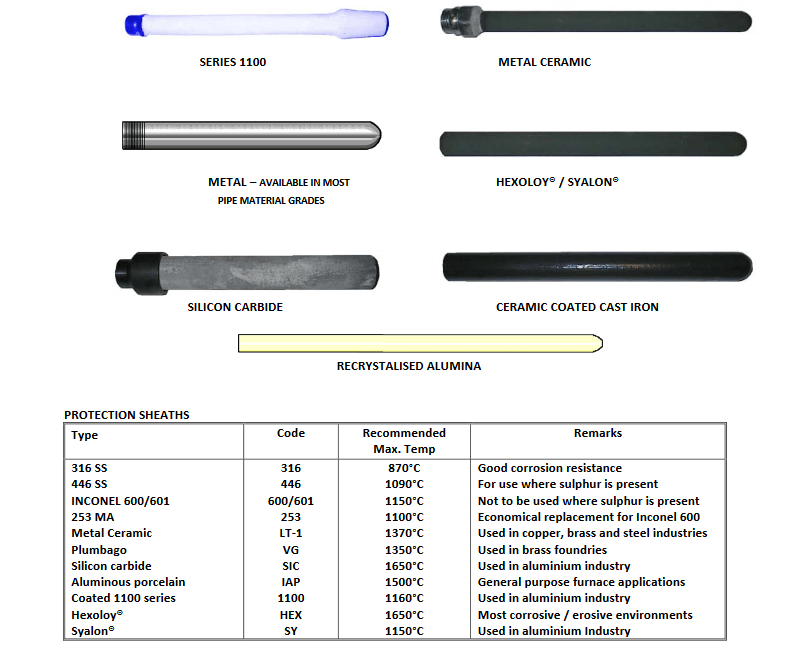

SPECIAL PROTECTION SHEATHS:

The above only covers the most commonly supplied thermocouples. We specialise in ‘Made to Order’ units and will quote against your specifications.

Hexoloy® Registered trademark of Carborundum Company.

Syalon® Registered trademark of Cookson.

Chromel® Registered trademark of Hoskins Manufacturing.

Alumel® Registered trademark of Hoskins Manufacturing.

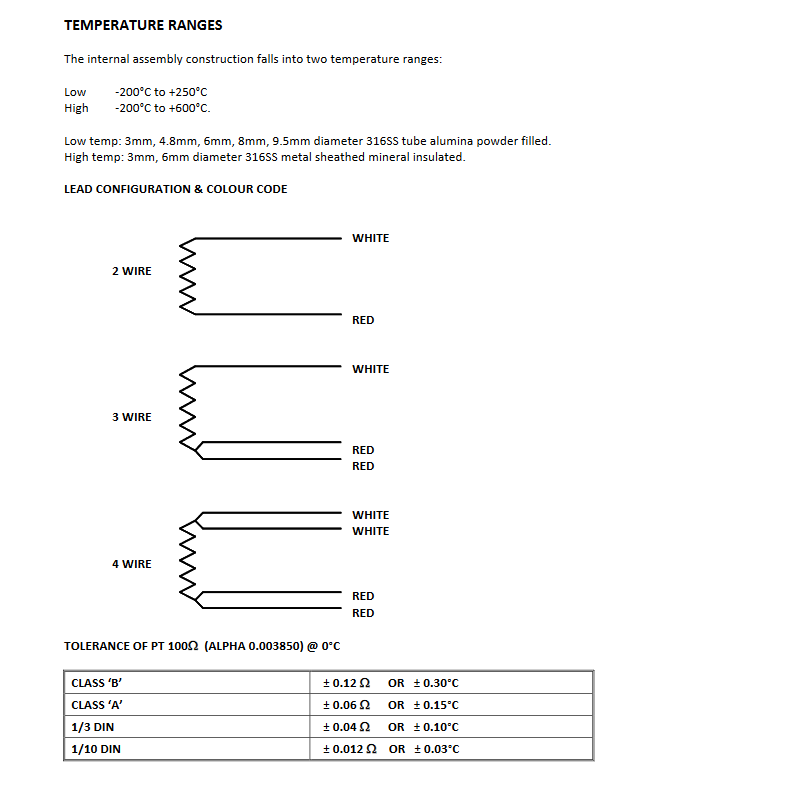

RESISTANCE THERMOMETERS;

Due to the need in the industry for greater accuracy and stability, the resistance thermometer (RTD) is becoming more widely used. The platinum RTD has a nominal resistance of 100ohms at 0°C, and a temperature coefficient of 0.00385 is emerging as a world standard.

DETECTOR TOLERANCE AND ACCURACY: The RTD bulbs used in Pyrosales’ assemblies conform to IEC 751‐1983 and in standard form are supplied to class ‘A’ tolerance. Other tolerances of class ‘B’, 1/3, and 1/10 Din are available on request. Also available are Nickel 100ohm and Platinum 130, 500, 1000ohms.

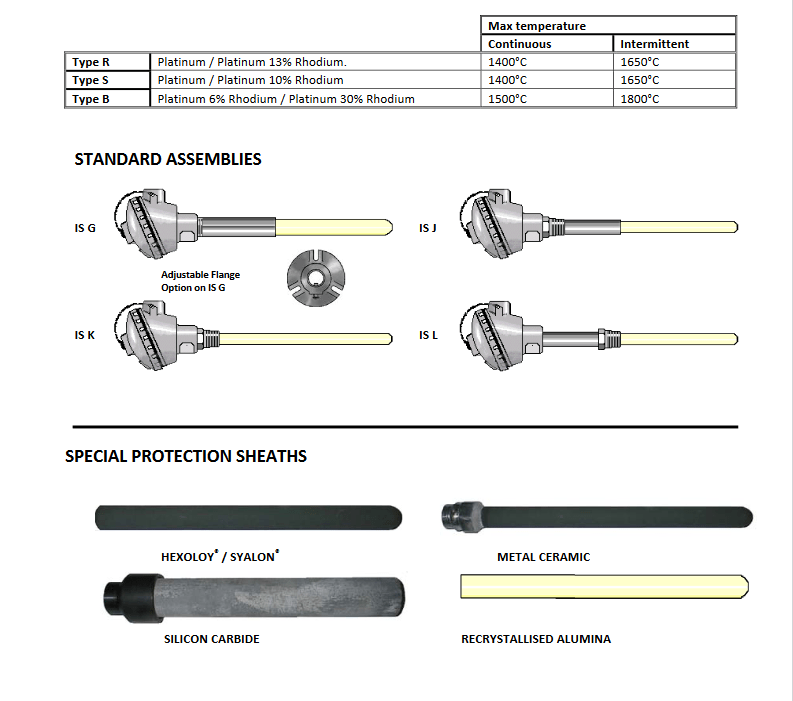

Rare Metal Thermocouples are used in applications where the temperatures exceed the working range of Base Metal Thermocouples, i.e. 0‐1300°C, or where greater accuracy is required such as in Standard Thermocouples. Wire size is typically 0.5mm in diameter.

e

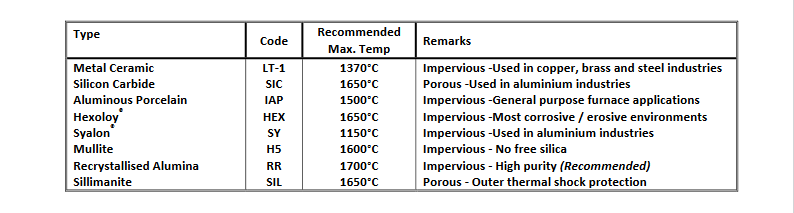

Rare Metal Thermocouples require protection sheaths to avoid contamination from the process. Details of these are shown in the table below:

the above are available on request. The above only covers the most commonly supplied thermocouples. We specialise in made‐to‐order units and will quote

against your specifications. Hexoloy® Registered trademark of Carborundum Company. Syalon® Registered trademark of Cookson.

METAL‐CERAMIC LT‐1;

General Information: UCAR metal‐ceramic LT‐l is a combination of a metal matrix, chromium, and a pure ceramic phase, aluminium oxide (alumina). It is composed 65% by volume of metallic phase and 35% by volume of ceramic phase. The material is slip cast, sintered, and then oxidised. Although the exact nature of the bond between the phases is not known, a physical‐chemical bond may be formed through the sharing of oxygen by the chromium and the alumina. There is

Slip casting is a process whereby finely divided solid constituents are put into liquid vehicle to form a colloidal suspension called a ‘slip’. This slip or suspension is poured into a porous plaster mould. The mould absorbs the liquid leaving the solids in the shape of the mould cavity.

Axial ID holes are obtained by drain casting which involves draining off the excess slip after the wall has built up to the desired thickness.

Physical Appearance: In general, UCAR metal‐ceramic LT‐l has a dull grey colour in the as‐produced condition, and a metallic appearance when either ground or machined. After the oxidising heat‐treatment, the surface colour is generally a dark green to black.

Properties: By the very nature of its constituents, UCAR metal‐ceramic LT‐l exhibits properties that are not found solely in either a metal or pure ceramic alone. LT‐l has excellent oxidation resistance and also resists wetting by many metals and alloys, as well as basic furnace slags. The chromium‐metal phase takes on a tightly bonded layer of chromium oxide which, together with the naturally inert nature of the alumina, provides this material with its remarkable resistance to oxidising atmospheres over 1200°C, good corrosion resistance, and the ability to resist wetting by molten metals. High thermal conductivity and the resultant excellent sensitivity to temperature changes account, in part, for its demand in the high‐temperature pyrometry field as a thermocouple protection tube.

LT‐l has good strength at temperatures where many high‐temperature metals melt. Above 1540°C, it begins to soften and becomes plastic. LT‐l thermocouple protection tubes have, however, been used successfully for dip immersion at a temperature of 1650°C. In use or service, care must be taken to avoid conditions of extreme thermal shock, extreme thermal gradients, mechanical shock, and impact.

Although LT‐l is superior to ceramics in all of these properties, it is less resistant to shock and impact than metallic alloys. Therefore, a standard thermocouple protection tube should be preheated to about 480°C before immersion in molten metal at 1100°C or higher. Whenever practical, the following preheat procedure can also be used: Hold the tube immediately above the molten metal for approximately one minute before immersing. This procedure proved to be adequate to prevent thermal shock failure in tests conducted. UCAR metal‐ceramic LT‐l exhibits good resistance to wear under conditions of sliding friction, as well as resistance to abrasion at high temperatures. The hardness of this material (Rockwell C 37) is more indicative of the crushing strength of the material than its true hardness because the individual particles have a greater hardness than the combined body. UCAR metal‐ceramic LT‐l is less porous than most compacts. There is no significant passage of gases through the body at high temperatures, except under a high vacuum. For the usual industrial application, it is sufficiently impermeable. For example, S02 and S03 gases have not penetrated LT‐l thermowells over a three year period to affect thermocouple wires.

In summary, UCAR metal‐ceramic LT‐l possesses several attractive properties:

• Non‐wetted by most molten metals and basic slags. • Good erosion resistance. • Good abrasion resistance. • Good oxidation resistance. • Good thermal conductivity. • High strength above the temperature at which most materials melt or otherwise fail. • Marketable by most standard shop practices. Applications:

The following is a list of recommended and non‐recommended applications for UCAR LT‐l Metal Ceramic. Recommended Applications

• Molten copper and brass to 1150°C intermittent and continuous immersions. • Corrosive SO2 and SO3 gas (to 1375°C) and SO3 and HF gas (to 1100°C).

• Open hearth furnace checker chambers to 1350°C. • Steel mill soaking pits to 1375°C. • Pelletising charter of Taconite refining operation to 1150°C.

• Molten zinc to 875°C. • Molten lead to 350°C • Basic steels and slags to 1735°C (intermittent) and 1375°C (continuous) in open hearth and general

foundry practices. • Calcining kilns to 1200°C. • Barium titanate (barium oxide service) to 1200°C. • Magnesium oxide calcining kilns. • Fluid bed cement process with severe corrosion and temperature to 1315°C (fluid method of producing builders’ cement). • Gas and ethylene cracking atmosphere. • Atmosphere directly above burning sodium (975‐1375°C). • Oil fired furnace chambers. • Atmosphere directly above the molten glass in an open hearth glass furnace.

• Molten silver solder. • Molten tin. • Borax flux. • Copper matte. • Boiling sulphuric acid ‐ 97%. • Blast furnace stove dome and bustle pipes.

Non –Recommended Applications:3

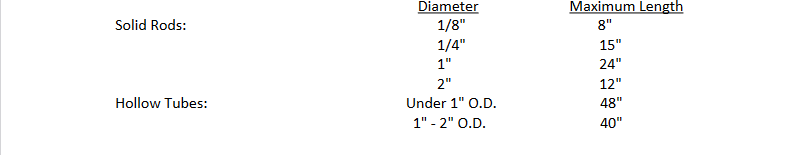

Thermocouple protection tubes, 7/8″ O.D. x 5/8″ I.D. up to 48″ long with ±1/16″ overall tolerances, are in stock for immediate shipment. Solid rods and ‘other type’ cast tubes are made‐to‐order items. The following designated sizes are typical capabilities.

Wall Thickness: 7/32” maximum, 1/8” minimum, 3/16” preferred, Rod Tolerance: All dimensions ±1/16″, Curvature: 1.3% measured chord to arc.

Hollow Tube Tolerance: All Dimensions ±1/16″. Straightness: 2” long probe with diameter 1/8″ smaller than tube I.D. will pass freely.

Miscellaneous: Rods and tubes in lengths greater than standard are available by coupling sections together. Also, the possibility of a redesign of a part, or shape, in order to make it amenable to the process, should not be overlooked if the product potential can offset the development work required.

This information is not to be taken as a warranty or representation for which we assume legal responsibility nor as permission or recommendation to practice any patented invention without a license. It is offered solely for your consideration, investigation and verification.

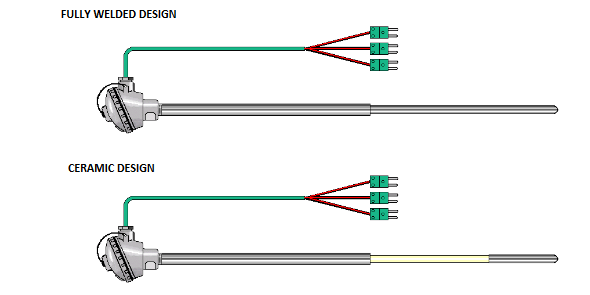

TERMINAL HEADS: Pyrosales stock an extensive range of thermocouple heads and terminal blocks for temperature probes. General purpose terminal head construction materials include Aluminium, Bakelite (thermoplastic), Polypropylene, Stainless Steel, and Cast Iron. Standard terminal blocks are manufactured in both ceramic and Bakelite with either 2, 3, 4, or 6 terminals. Spring‐loaded terminal blocks are available with either 4, 6, or 8 terminals.

Explosion proof (Ex ‘d’) terminal heads are also available and are covered in a separate catalogue sheet.

THERMOCOUPLES FOR THE GLASS INDUSTRY: Pyrosales have been producing temperature solutions for the Glass Industry for more than 20 years.

Our products are constantly being updated to meet the challenging and ever‐changing production techniques of glass manufacture. We specialise in custom‐designed and engineered solutions.

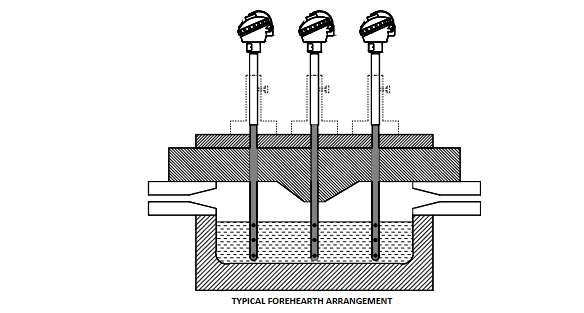

Installation of thermocouples across the forehearth allows for accurate monitoring and control of the glass temperature. As the viscosity is temperature dependent, it results in an homogenous glass flow.

For the glassmaker, there are a number of benefits to this accurate control: • Optimum weight of each container. • Reduction in tank wear, which increases the tank life. • Overall cost savings by higher yield of containers per batch.

Molten glass is a harsh environment, and any thermocouple immersed in it must be able to withstand the severe conditions. The Tri‐level assembly is protected from the aggressive nature of the glass by an outer sheath of ODS® Platinum or a Platinum/Rhodium alloy, and has three measuring

SINGLE‐POINT IN GLASS THERMOCOUPLES; Some applications only require single‐point measurement. The same design style as a tri‐level can be used but with only one thermocouple junction. This junction can either be at the bottom or at some other elevated point.

TUBE AND WIRE THERMOCOUPLES:

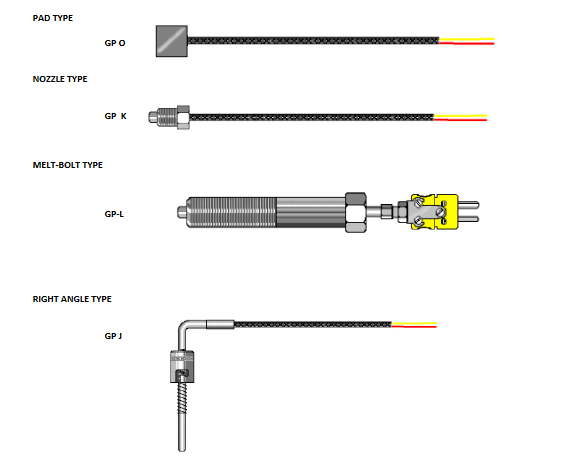

TYPICAL APPLICATIONS: • Plastic injection moulding machines • Food processing equipment • Plating baths • Industrial processing • Medical equipment

• Packaging equipment • Liquid temperature measurement • Oven temperature control

bends to any angle, thus eliminating the need to stock numerous styles.

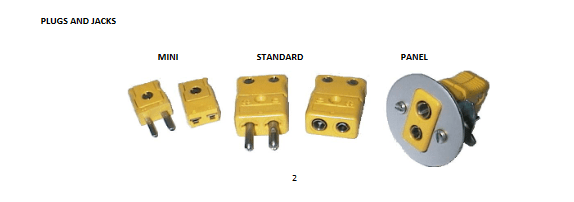

Plugs and Jacks: Pyrosales has a large selection of plugs, Jacks, Clamps and Mounts.

Pyrosales’ engineers have over 47 years of experience producing specialised solutions for high temperature applications. Whether this is an infrared temperature monitoring system or a more traditional contact temperature system, we can design and supply the most effective temperature and process control equipment for furnaces, ovens, kilns, and other extreme heat applications.

FOR MORE INFORMATION CONTACT US

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.