1300 737 976

Call us

Live Chat

Call us

By Richard Hosier TRM – MICC Ltd

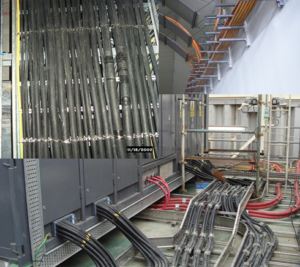

Whilst we may understand this, we seldom think much about cables because the electric wiring systems we use are mostly hidden and embedded in the construction, ceiling spaces, riser shafts or wall cavities. Because cables are installed by many different trades for different applications, often in polymeric conduit and ducting systems, what is not often realized is that the many miles of cables and many tons of plastic polymers which make up the cable installation system can represent one of the biggest fixed fire loads (fuel source) in the building. This point is certainly worth thinking more about.

Fire Spread & Flame Retardance

Electrical cables are frequently blamed by the media and fire authorities as to the cause of fires, however, it is often not the failure of the cable which starts a fire but the misuse of the cable by frayed or damaged insulation, overloading due to incorrect or insufficient circuit protection, short circuit or overvoltage. These situations can cause high temperatures in the cable conductors or electrical arcing which may heat the cable insulation and any surrounding combustible materials to start a fire.

Most common flexible cables are made from hydrocarbon-based polymers. These base polymers are not usually flame retardant and have a high calorific value so cable manufacturers add chemicals to make them more suited to electrical cable use. Halogens like Chlorine are particularly good additives that help retard flame propagation and don’t significantly impact the dielectric properties of the polymer, so Halogens are used in both cable insulations and in cable sheaths. These halogenated polymers (example: PVC) also have a negative side-effect because in the fire they will release the halogens as halides which are extremely toxic and when combined with moisture in the eyes, nose, mouth, and lungs are very irritant. Often standard PVC cables may also release large amounts of acrid smoke.

Often, designers realize the dangers of fire spread, halogens & toxic gasses, plus the smoke releasing from cables in the fire so they specify cables to have ‘Halogen Free’ and ‘Flame Retardant’ properties. In these cases, cable manufacturers need to use other non-halogenated materials, mostly with flame retarding fillers like alumina-trihydrate (ATH). While effective in retarding flame propagation, these fillers often negatively affect the polymer by reducing dielectric performance or affecting mechanical & water resistance. For this reason, additives like ATH are mostly used only in cable jackets. Halogen-Free Flame Retardant cables often use a more pure polymer like Polyethylene (PE or XLPE) or EPR for the insulation which has good electric and mechanical properties but may not be very flame retardant.

Fire Propagation performance

Often the best flame retardant cables are halogenated because both the insulation and outer Jacket are flame retardant but when we need Halogen Free cables we find it is often only the outer jacket that is flame retardant and the inner insulation is not. This has significance because while cables with a flame retardant outer jacket may pass flame retardance tests with an external flame, the same cables when subjected to high overload or prolonged short circuits have proved in university tests to be highly flammable and can even start a fire. This effect is known and published by Olex Cables Australia at the 8th International Conference on Insulated Power Cables in Versailles, France. What this means is your flame retardant cables may not be flame retardant at all in severe short circuit or overload conditions!

Singapore MRT 2013 – Newton Underground Station. Cable overloaded and caught fire ” Even a small cable fire creates alot of smoke”

In Australia, unlike any other country, AS/NZS3008.1.1:2017 has tables allowing some cable designs to operate at conductor temperatures to 110°C. Whilst technically possible for the cables, what has not been fully considered by Australian standards is the intrinsic change this cable operating temperature may have on the cable’s flammability. Where cables are required to be flame retardant to Australian Standard test methods AS/NZS60332-3 it is concerning these tests are not conducted on cable samples preconditioned to the operating temperature, rather commencing at room temperature. It is well known the hotter a material is the more easily it will burn so designers and users of cables that claim to meet these standards may be surprised to learn their cables might not be flame retardant at all when installed and used at their rated operating temperature.

In America, many building standards do not require halogen free cables. Certainly this is not because Americans are not wisely informed of the dangers, rather the approach taken is that: “It is better to have highly flame retardant cables which do not propagate fire than minimally flame retardant cables which may spread or contribute to a fire” (a small fire with some halogens may be better than a large fire without halogens).

Europe, UK, Australia and many countries around the world have a different approach: Halogen Free and Flame Retardant. Whilst this is an admirable approach, the reality is rather different: In asking for both flame retardant and halogen free properties, cable manufacturers often compromise between high flame retardance with halogens or reduced flame retardance without halogens.

Enclosing cables in steel conduit will reduce flame propagation at the point of fire but hydrocarbon based combustion gasses and smoke from the decomposing polymers will propagate along the inside of conduits to switchboards, distribution boards and junction boxes in other parts of the building where any spark such as the opening or closing of circuit breakers, or contactors is likely to ignite the combustible gasses leading to ignition or even explosion and spreading of the fire and smoke to other locations.

The primary importance of fire load

To provide cables which are halogen free, cable makers most often choose polymers like polyethylene (PE & XLPE) because it is easy to process and cheap however, although polyethylene is halogen free it has a naturally high fire load.

The following table compares the fire load in MJ/Kg for common cable insulating materials against some common fuels. The Heat Release Rate and volatility in the air for these materials will differ but the fuel added to a fire per kg and the consequential volume of heat generated and oxygen consumed is relative.

Pic 1

When considering fire safety we must first understand the most important factors. Fire experts tell us most fire related deaths in buildings are caused by smoke inhalation, temperature rise and oxygen depletion or by trauma caused by jumping in trying to escape these effects. So let’s take a look at these factors as they relate to the electrical cable system:

Smoke:

The first and most important aspect of smoke is how much smoke? Typically the larger the fire the more smoke is generated so anything we can do to reduce the spread of fire will also correspondingly reduce the amount of smoke. Highly flame retardant cables with a high oxygen index may help here because they may limit the fire spread.

Smoke will contain particulates of carbon, ash and other solids, liquids and gasses, many are toxic and combustible. In particular, fires in confined areas like buildings, tunnels and underground environments cause oxygen levels to drop near the fire source and this can contribute to incomplete burning and smoldering which may produce increased amounts of smoke and toxic by-products including CO (Carbon Monoxide). As we know presence of halogenated materials will release toxic halides like Hydrogen Chloride together with many other toxic and flammable gasses in the smoke.

For this reason common British, IEC and Austrlian (AS/NZS61034) smoke tests conducted by burning cable samples in large 3 meter³ chambers with plenty of air may provide misleading smoke figures because complete burning in flame can release less smoke than partial incomplete burning or smoldering which is likely in practice (in America NFPA 130 calls for smoke tests in both flaming and non-flaming modes). Simply specifying low smoke cables to common British or IEC standards then thinking this will provide a low smoke environment during a real fire may unfortunately, in practice, be of little help for the people actually involved.

Halogens, Toxicity, Oxygen depletion and Temperature rise

It is concerning that the UK, Europe, Australia and other countries often adopt the concept of halogen free cables without fully addressing the subject of toxicity. Halogens released during combustion are extremely toxic but so too is carbon monoxide and this is not a halogen gas. It is common for specifications to call for halogen free cables and because of this, encourage the use of Polyethylene because it is halogen free. Burning Polyethylene (which can be seen from the table above has the highest MJ fuel load per Kg of all insulations) will generate almost 3 times more heat than an equivalent PVC cable. This means that burning polyethylene will not only generate almost 3 times more heat but also consume almost 3 times more oxygen and produce significantly larger amounts of Carbon Monoxide especially with partial or incomplete burning. Given that it is carbon monoxide which is statistically responsible for most toxicity deaths in fires this situation is at best alarming! (Carbon Monoxide is a colorless and odorless toxic gas which inhibits the blood hemoglobin from absorbing oxygen. Prolonged exposure results in asphyxiation).

The fuel elements shown in the table above (pic 1) indicate the amount of heat that will be generated by burning 1kg of the common cable insulations tabled. Certainly this volume of heat will accelerate the burning of other adjacent materials and may help spread the fire in a building but importantly, in order to generate the heat energy, oxygen needs to be consumed. The higher the heat of combustion (MJ/Kg) the more oxygen is needed, so by choosing insulations (even if Halogen Free) with high fuel elements is adding significantly to at least four of the primary dangers of fire: Temperature rise, Oxygen depletion, Toxic gas emission, and Flame spread.

Conclusion – Fire Load:

The popularity of “Halogen Free” properties while ignoring the other toxic elements of a fire is a clear admission we do not understand the subject well nor can we easily define the dangers of combined toxic elements or human physiological response to them. It is important however, that we do not continue to design with only half an understanding of the problem. While no perfect solution exists for organic based electric cables, we can certainly minimize these critically important effects of fire risk:

Essential Life Safety and Fire Fighting circuits

Unlike other cables, fire resistant cables have to work even when directly exposed to the fire to keep essential equipment working: Fire alarms, Emergency Lighting, Emergency Voice Communication, Fire Sprinkler pumps, Fireman’s Lift sub-main, Smoke extraction fans, Smoke dampers and shutters, Stair pressurization fans, Emergency Generator circuits etc..

With the release of AS/NZS3013:2005, Australia has perhaps a better certification regime than Europe or UK for fire rated wiring systems (The American UL2196 is perhaps the world’s best fire resistance protocol for wiring systems as it requires fire and water testing in both horizontal and vertical configurations). However, any wiring system (cable or bus duct) required to operate in fire must not only account for the electrical integrity of the circuit in order to ensure the reliable function of the life safety and firefighting equipment connected but also for the effects of fire on voltage drop, reduced conductor conductivity due to increased conductor resistance at fire temperatures and the additional ohmic heating generated by carrying the required load under these conditions. Unfortunately, our current standards do not. What this means is that it is entirely possible many essential wiring systems installed today and the essential equipment connected, can fail if subjected to serious fire events due to fire induced increased voltage drop or by the failure of conductors to carry the required current at fire temperatures.

Research by Universities, Institutions, and Authorities in Australia and around the world have identified that for modern above ground cellulosic buildings, the use of light weight thermoplastic building materials, synthetic foams, and fabrics, along with synthetic materials and plastic contents have significantly increased dire loads resulting in time temperature fire profiles well above the original parameters of the existing, early 1900’s test protocol ISO834-1 (AS/NZS1530pt4) as mandated by the Australian NCC. Underground environments are also known to exhibit very different fire profiles to those in above ground cellulosic environments. Specifically, in confined underground public areas like road and rail tunnels, underground shopping centres, car parks, etc., fire temperatures can exhibit a very fast rise time and reach temperatures well above those in above ground buildings. The UK British Standard BS8519:2010 clearly identifies underground public areas such as car parks as “Areas of Special Risk”. In these environments, more stringent test protocols for fire resistance including for electric cable systems may need to be specified by designers..

It should be noted that national standards and building regulations are drafted as minimum general requirements and that should a building, project, or environment be known to have more demanding emergency conditions or fire risk than considered in the standards, then it may be the responsibility of the professional engineer and project owners to require additional performances.

Time temperature profile of tunnel fires of HGV trailers with different cargo

Haukur Ingason and Anders Lonnermark of the Swedish National Testing and Research Institute presented a paper at the First International Symposium in Prague 2004: Safe and Reliable Tunnels.

For metros road and rail tunnels, hospitals, health care facilities, underground public environments like our popular mega shopping precincts, very high rise, theaters, public halls, Government buildings, airports etc., this is particularly important. Evacuation of these public environments with children, aged and disabled people, can be very slow during emergencies, and it is our responsibility to ensure everyone is given the very best chance of safe egress during fire emergencies.

For many power, control, communication, and data circuits there is one technology available for all the issues raised in this paper. It is a solution that is frequently used in demanding public buildings and has been employed reliably for over 80 years. MICC cable technology provides a comprehensive solution to all the problems associated with the fire safety dangers of modern flexible organic polymer cables.

The copper jacket, magnesium oxide insulation and copper conductors of MICC cables ensure the cable is effectively fireproof. MICC cables have no organic content so simply cannot propagate flame or generate any smoke. The zero fuel load of these MICC cables ensures no heat is added to the fire and no oxygen is consumed. Being inorganic these MICC cables cannot generate any halogen or toxic gasses at all including Carbon Monoxide. MICC cable meet all of the current and building fire resistance performance standards in Australia and are seeing a significant resurgence in Australia and overseas.

Many engineers have previously considered MICC cable technology to be “old school’ but with the new research into the real fire performances of many polymer based wiring systems, MICC cable systems represent a viable and holistic solution, which in consideration of Total Cost of Ownership, can often be provided at lower prices too.

Just like Flexible Polymeric Fire Resistant Cables, MICC cable technology is available from Pyrosales Pty Ltd.

For more information on Pyro / MIMS cable, click here.

For any information, please contact us or call 1300 737 976.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.