1300 737 976

Call us

Live Chat

Call us

What is an Infrared Pyrometer?

An Infrared Pyrometer is a type of remote-sensing thermometer used to measure the temperature of distant objects. Various forms of pyrometers have historically existed. In the modern usage, it is a device that from a distance determines the temperature of a surface from the amount of the thermal radiation it emits, a process known as pyrometry and sometimes radiometry.

A Pyrometer consists of an optical system and detector. The optical system focuses the energy emitted by product being tested onto the detector, which is reactive to the radiation. The output of the detector is corresponding to the amount of energy radiated by the tested product, and the response of the detector to the specific radiation wavelengths. This output can deduce the objects temperature. The emittance, of the object is an important variable in converting the detector output into an accurate temperature signal. The physics behind the broadcasting is known as Planck’s Law of Thermal Radiation. The IR range falls between the visible portion of the spectrum and radio waves. IR wavelengths are usually expressed in microns, with the IR spectrum extending from 0.7 to 1000 microns. Only the 0.7-14-micron band is used for IR temperature measurement.

What are the Advantages of using Infrared Pyrometers in The Glass Industry?

Why is the Role of Wavelength or Spectral Range important in the Selection of an Infrared Pyrometer?

The right wavelength selection is very important for all glass applications.

The following table summaries the glass application and our recommended products for the same.

What is Float Glass Application?

Once the glass passes out of the Tin bath it passes into the Annealing Lehr where it is subjected to cooling so that glass becomes resistant to strain, doesn’t crack and most importantly cut ability of the glass will be good .Once the glass is properly annealed it exits the Lehr and then the

glass is cut by machines and transported. The regions within the float glass manufacturing process

where temperature measurement is crucial are Working tank, Canal, Tin bath and Annealing Lehr.

Application: Working Tank

Application: Working Tank 600°C

600°C

What is Container Glass Application?

hearths/feeders. The molten glass then flows into the gob from where it is dropped into the various moulds where the glass forming is done. The most important and critical region is the Forehearth /Feeder. Proper temperature is to be maintained in the Fore hearth. By doing so it can be ensured that the molten glass reaching the gob is in homogeneous state. As we know change in temperature is critical to glass viscosity. A slight change leads to changes in viscosity as well.

Recommended Product: AST 450G2

Temperature measurement is crucial for maintaining homogeneous condition of the molten glass exiting the tank.

Application: Feeder / Forehearth

Recommended Product: AST 450G2

The AST 450G2 is the right solution for the monitoring of temperature in the Fore hearth. The fast response time is useful in monitoring changes in temperature range.

Pyrometer contains small optical head which makes it easier to reach the harsh locations and the Fibre Optic Cable can withstand ambient temperature up to 250°C very easily. The accessory such as air purge unit helps in purging and keeps the optical lens clean, and the mounting system provides

proper support to the pyrometer.

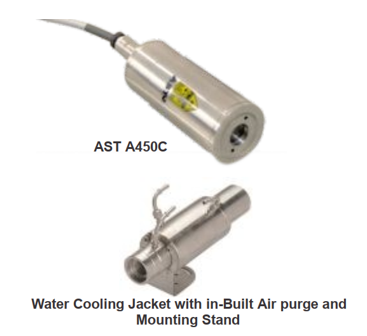

Recommended Product: AST A450C

Efficient temperature control helps in achieving the desired container wall thickness. With the use of infrared pyrometer, the correct gob temperature is achieved before entering the next stage. This application demand fast acting infrared pyrometers. The two-colour pyrometer provides a response

time of 20msec. Pyrometer with water cooling jacket is recommended for this application.

Application: Glass Mould

Recommended Product: AST A250 single wave infrared non-contact on-line digital pyrometer with peak hold and software for continuous data storage and available small spot sizes

Pyrosales has extensive knowledge and experience in temperature management and process control. We provide advice, design, repair, and fabrication to our clients on a wide range of industries, uses, and capabilities of temperature management.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.