1300 737 976

Call us

Live Chat

Call us

Pyrosales distribute Conax fittings and glands, we have found that the quality of Conax products have the standards which our clients expect from us. Like the EG Gland, Conax EGT Glands

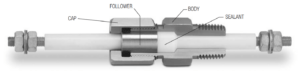

EGT gland bodies with NPT threads or SAE threads are constructed from 303SST standard. Weld-neck style glands are constructed from 316LSST standard. Caps and followers for all styles are constructed from 303SST standard. Many optional materials are also available. Cap Style A offers a mounting thread only. Cap Style B provides threading on both ends for attachment to conduit or terminal heads. Alternative sealant materials are available.

Conductors are available in Copper, Nickel and 303SST. Use of Nickel rather than Copper is recommended in oxidizing atmospheres. For further information on conductor selection, Custom conductors, such as nickel-plated copper, are available. Please contact us for more information.

• Temperature Range: -300˚ F to +450˚ F (-185˚ C to +232˚ C)

• Pressure Range: Vacuum to 2,500 PSIG (170 bar) – see Pressure Ratings in Specifications Chart.

• Voltage to 8000 VDC

• Amperage to 525 amp

• Supplied with or without conductor

Accessories

The replaceable sealant permits repeated use of the same fitting. Electrodes can be easily assembled or replaced in the field. To replace the sealant or element, simply loosen the cap, replace the necessary items, re-lubricate and re-torque the cap. Glands are supplied factory lubricated. When reused, the glands should be re-lubricated to maintain the published torque and pressure ratings. If glands are cleaned prior to assembly, they should be re-lubricated. On weld mount models, the heat from the welding process will destroy the lubricant. These models must also be re-lubricated prior to use. Contact us for more information on the lubrication kit.

Pyrosales has extensive knowledge and experience in temperature management and process control. We provide advice, design, repair, and fabrication to our clients on a wide range of industries, uses, and capabilities of temperature management. Contact us at anytime on 1300737976 or CLICK HERE FOR A QUOTE

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.