1300 737 976

Call us

Live Chat

Call us

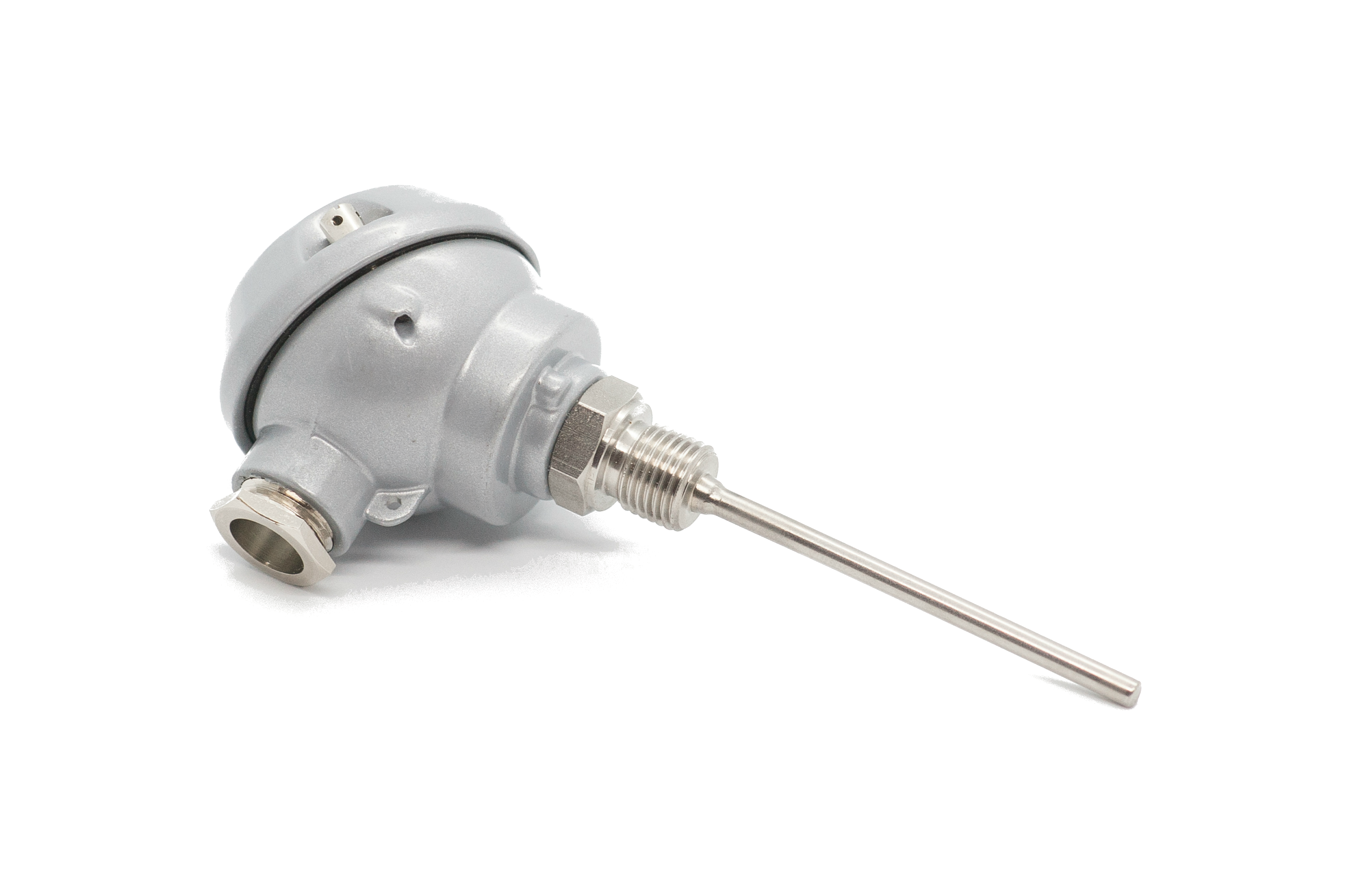

The manufacturing of a thermocouple is a process that can be easy or difficult depending on the specification and application where the thermocouple is intended to be used.

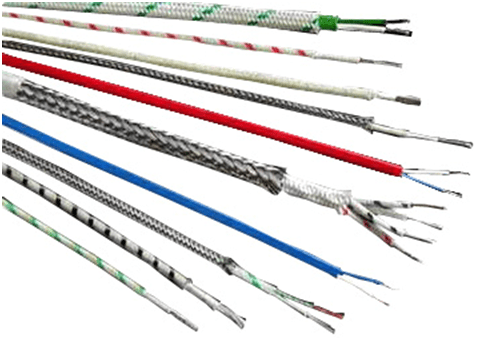

Pyrosales offer a wide selection of thermocouple wire and cable, to cater to a wide range of applications and temperature ranges. Choosing from Synthetic, Tape, fiberglass, PTFE and PVC.

Difficult thermocouples require specialised manufacturing, contact Pyrosales to manufacture with supplying the specification, dimension and application in which the thermocouple will be used in.

Type B: Used extensively in the steel and iron industry to monitor temperatures and chemistry throughout the steel making process.

Type C: Widely used in space vehicles, nuclear reactors, industrial heating, or wherever extremely high temperatures may be present. Also used in high-pressure research. Well suited for vacuum furnaces at extremely high temperatures.

Type E: Used in sub-zero, oxidising or inert applications. Ideal for cryogenic, pharmaceutical, and chemical applications where critical measurements are required in small increments.

Type J: Recommended for vacuum, inert, and reducing atmospheres. The thermocouple can be used exposed or unexposed.

Type K: Used for measurements in many different types of environments such as water, mild chemical solutions, gases, and dry area. Found in engines, oil heaters, and boilers. Used as thermometers in hospitals and the food industry.

Type N: Has outstanding thermoelectric stability. Can be used in vacuum or controlled atmospheres. Developed to replace type K in nuclear applications.

Type R and Type S: Heat treating and control sensors, semiconductor industry, glass manufacturing, ferrous and non-ferrous metals.

Type T: Used in food monitoring and environmental applications.

If you require more information please contact us on 1300 737 976.

Copyright © 2022 Created by Pepper Digital

Disclaimer – Images for illustrative purposes only and may not be representative of the actual resolution of the camera shown.